Metal machining, Engineering production

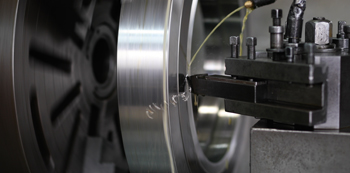

The activity of our company is focused on machining of metals using traditional technologies, i.e., turning and milling.

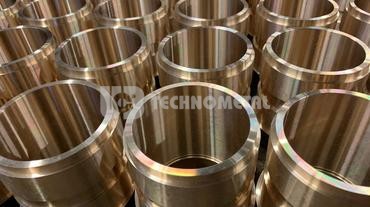

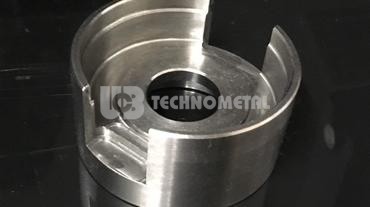

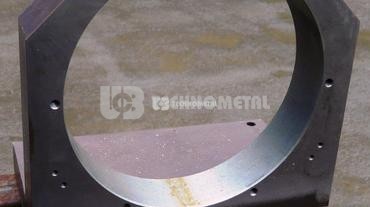

We produce precision parts according to customer drawings for general engineering with a wide range of applications in industry. Our greatest specialisation is the machining of flanges, labyrinths, sliding sleeves and rails, non-standard pulleys, crane travelling wheels and machine tool tables.

We offer precision metal machining – semi-finished products and castings in all cast iron, steel (Aluminium, bronze,brass and copper). The workpiece size is max. 600 kg handling weight. Maximum dimensions of machined surfaces up to 400x500x900 mm for flat machining and D 550 mm for rotary machining.

We design our own jigs and fixtures in CAD Cam software, and machining programs in Solidworks 2019. All parts are supplied with a full measurement report and material certificate.

According to your demand and drawing documentation we will prepare a quotation for price, delivery and terms of sale. Send us your request for the production of parts and components together with drawings to our email or contact us by phone.

All our engineering production services are provided at a high level of Quality and production according to the highest ISO 9001:2015 standards. Our qualified staff handle each order individually, from the initial consultation, through to the optimal material solution, price calculation and production and processing and delivery CNC MILLING.

Precision machining

We invest in the latest technologies and equipment for various degrees of precision, and we use professional technological software to prepare programs for CNC precision machining.